Materials

Renown Group is highly experienced in manufacturing using a wide range of materials. Due to the multiple industries in which we operate, this flexibility is demanded from our clients.

Our materials range includes:

- Structural Steel

- High Strength Steel

- Wear Resistant Steel

- Corrosion Resistant Alloy

- Armour Steel

- Aluminium Stainless Steel

- Exotic Metals

- Acoustically Enhanced Steel

Armoured and High Strength Steel

Renown Group has significant experience in fabricating and machining high strength, wear resistant, corrosion resistant and armour materials. This includes:

- Def-Stan 95-24

- Armox

- Weldox

- Hardox

- MIL DTL 12560K

- Secure materials

- S690QL

- S960QL

- Inconel 625

Our capabilities also include the fabrication and machining of RQT grades and fabrication of steel structures up to 10 tonnes in ferrous and non-ferrous metals.

Exotic Steel

Over 25 years, Renown Engineering has developed substantial experience in fabricating and machining exotic steels such as:

- Maraging steel

- High grade stainless steel

- Super Duplex

Our expertise enables us to manufacture exotic steel components and meet our customers’ most challenging requirements.

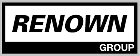

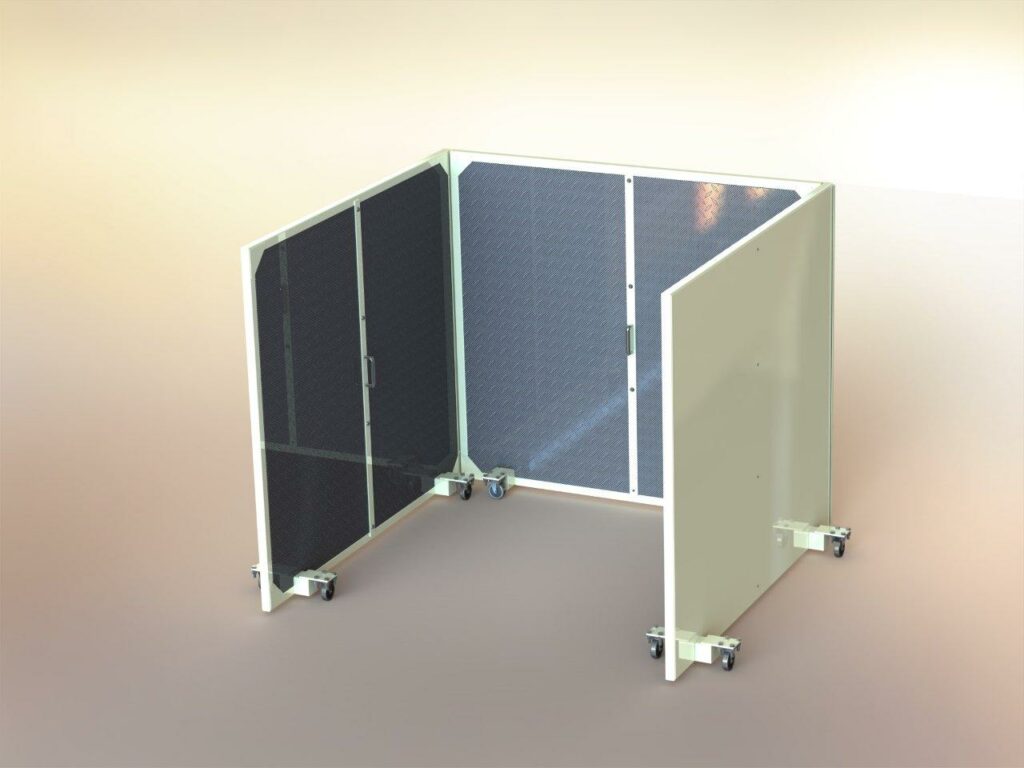

SDS: Acoustically Enhanced Steel

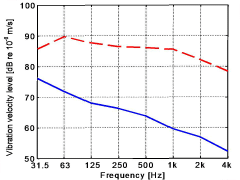

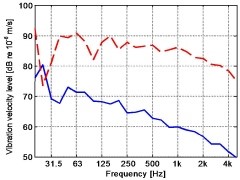

Renown Engineering has exclusive access to use Sound Dead Steel, an enhanced laminate steel product which provides noise and vibration reduction.

Sound Dead Steel can be incorporated into customer products to acoustically enhance the product and prevent noise and vibration transmission.

Renown Engineering has successfully incorporated Sound Dead Steel into the design and manufacture of acoustic enclosures and other structures to reduce noise and vibration.

SDS Products

Sonphonon™ Laminated Steel

Laminated Steel is available in a variety of thickness and sheet size. SDS can make laminates from 1mm to 8mm thick in aluminium, cold rolled, hot rolled, stainless and galvanised steels, including automotive grades. Sheets can be de-coiled to most lengths, common widths are 1000mm, 2000mm and 1500mm. SDS also provide a cutting and profiling service.

Sonphonon™ Self Adhesive Dampers

Self Adhesive Dampers are also available in a variety of thickness, grades of steel/aluminium and sheet size. Thickness can be from 0.5mm to 4mm. Grades and sizes are the same as the laminates.

Sonphonon™ Flexible 2 Pack Adhesive

Flexible 2 Pack Adhesive is a special adhesive which doesn’t glass when cured, this means impacts won’t shatter it and because it remains slightly flexible it transmits energy into our damped steel more efficiently. It also helps bond our laminated dampers to rough surfaces as it can fill up to 3mm.

Manufactured Products

- Acoustic Enclosures & Guards bespoke design service, we can design and fabricate or build to your drawings.

- Portable Acoustic Screens and blankets to place or hang around noisy machinery or to create a haven.

- Industrial Acoustic Absorbent Wall Panels in standard panel sizes or made to measure acoustic panels for wall mounting to reduce resonance and reflected sound.

- Skids For Power Packs & Gen Sets we can manufacture skids to GNV standards for offshore and onshore use.

- Quiet Extract Fan Technology designed by the INVC.co.uk, manufactured and installed by Sound Dead Steel.

SDS Self Adhesive Dampers

SDS produce range of steel/aluminium vibration dampers which are available in 2000mm*1000mm, 2500mm*1250mm, 3000mm*1500mm or cut to size. The thickness of the material can be specified from 0.5mm up to 4.0mm

Avoids Fabrication Issues

Folding a laminated SDS sheet can result in slippage between the two layers of steel. This is avoided by fabricating in the traditional way and bonding the SDS dampers on afterwards, acoustic benefits are not affected.

Avoids Welding Issues

Welding acoustic laminates can be tricky as the polymer often isolates the two layers of steel. One solution is to fabricate and weld the traditional way, then apply an SDS damper to the flat areas avoiding welds and folds.

Powder Coating

Laminates and dampers can be supplied with high a temperature polymer or silicone so dampers can be fitted prior to anodising or powder coating.

Low Cost Solution

SDS dampers are an effective way to solve potentially expensive noise issues.

Lighter Construction Saves Costs

The fabrication can be made out of a thinner gauge of steel as the constrained layer damping principle does not rely on mass to reduce vibration.

Metal Fatigue

SDS also has the additional benefit of helping to reduce metal fatigue by damping out harmful vibrations & harmonics, which makes it ideal for vibratory feeders and chutes.